We have been involved in a range of sub-sea pipeline projects over the years – ranging from small diameter pipes carrying water supply to offshore communities, through to large diameter gas and liquid trunklines carrying product from offshore rigs to onshore processing plants. All have presented unique technical challenges associated with dynamic seabed morphology, usually compounded by being located in cyclone affected regions

We have been involved in a range of sub-sea pipeline projects over the years – ranging from small diameter pipes carrying water supply to offshore communities, through to large diameter gas and liquid trunklines carrying product from offshore rigs to onshore processing plants. All have presented unique technical challenges associated with dynamic seabed morphology, usually compounded by being located in cyclone affected regions

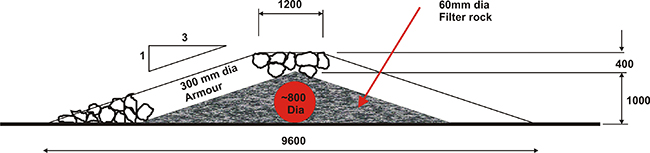

There are several secondary stabilisation techniques that can be used to improve the on-bed stability of subsea pipelines. However, among the most common stabilisation methods are rock dumping, gravity anchors, rock bolts and trenching.

Most of the pipeline secondary stabilisation methods are costly, time consuming and have significant construction implications. In the case of rock dumping, for example, a relatively large quantity of quarry rock must be transported from inland quarries and placed on the seabed over or alongside the pipelines. Challenges facing the pipeline engineer include alignment selection, design basis definition, pipeline stability analyses, operational requirements and construction method definition. This also includes how to maintain significant construction cost reduction and operational reliability of the pipeline system.

The design of pipeline secondary stabilisation has traditionally followed a deterministic approach that applies empirical equations for preliminary design, often followed by physical modelling for design verification and optimisation.

The design of pipeline secondary stabilisation has traditionally followed a deterministic approach that applies empirical equations for preliminary design, often followed by physical modelling for design verification and optimisation.

Our coastal engineers have considerable expertise and experience in this aspect of design optimisation. This expertise has been developed over more than 30 years – commencing with significant involvement in the first major project in Australia where secondary stabilisation in the form of rock berms was investigated and implemented (for the North West Shelf Rankine project). Our engineers proposed and implemented physical modelling of stabilisation options under combined wave and current action.

We have assisted our clients in the oil and gas industry to develop the most cost effective state-of-the-art secondary stabilisation systems:

- for Woodside – the first Trunkline at North Rankine; the second trunkline (TSEP); and most recently for the Browse Project;

- for Shell – the Maui B pipeline in the early 1980’s

- for Chevron – the Gorgon pipelines; and

- for the KUPE project in New Zealand.

In recent years, as modelling facilities have become more sophisticated worldwide, our services have included assessing internationally available physical modelling facilities, and the subsequent supervision and technical review of physical modelling work and its outcomes at various overseas facilities.

Projects

- Browse LNG Development Project – Physical Modelling of Secondary Stabilisation Options

- Gorgon Gas Project – Physical Modelling of Secondary Stabilisation Options

- Domgas Pipeline Backfill